Revolutionizing product tracking: Low cost unique plastic identifier using image processing

Berkeley, CA, November 2020 — Implicit Plastic Identifier (IPI). As part of the DataX Program, the IPI team has developed a novel method for the unambiguous tracing of plastic components, enabling a quality life cycle control system for all plastic-dependent sectors.

In industries such as medical or automotive, clear product tracking s is required to identify batches of faulty material and recall the entire series. However, uniquely identifying mass-produced plastic parts is difficult. There exists a system designed by the company “Matriq”, proposing to modify all injection-molding machines to print a scannable code onto plastic components. Despite appearing failproof, their implementation is extremely difficult and expensive.

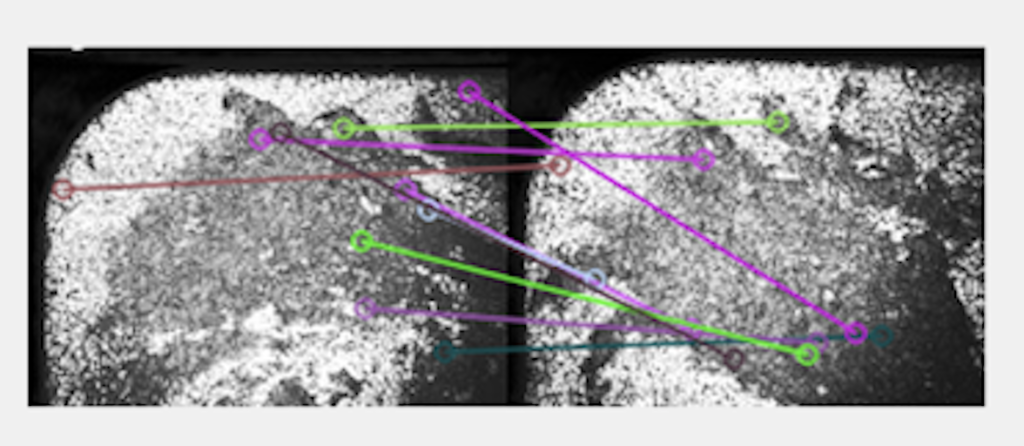

There is, in fact, no need for modification to the existing process of producing plastic. The IPI team’s solution only requires a microscope – inexpensive and widely available – to scan an assigned part of the plastic surface after production. In the event of a defect, the product can be rescanned and uploaded through an intuitive user interface. At the backend, the software performs computer vision algorithms across the database of recorded scans to find a direct match. Then relevant product information (e.g. material, manufacturer, date) are displayed, guaranteeing complete traceability. For the end client, this unlocks quality control systems that span the plastic’s entire life cycle.

“If this system works, it could mean the end of Matriq”

Guido Schuster, Professor for Image Processing and Artificial Intelligence

Matriq is giving each product a unique identity by applying a readable code on it. IPI on the other side are embracing the unique identity most plastic parts already have: their surface. The surface texture serves as the ‘fingerprint’. A microscope can be easily sourced to capture this scan, which will be fed to our state-of-the-art image matching software. Leveraging the nature of injection-molded plastic, IPI has created an easier, cheaper, and faster solution than Matriq, all without any loss of performance.

The IPI team was created as part of the DataX course at the University of California, Berkeley in collaboration with the University of Applied Sciences OST. The team is supported by Ikhlaq Sidhu (Faculty Director, Chief Scientist at SCET) and Guido Schuster (Head of the ICAI and professor for Image Processing and AI).

Felicity Liao

CEO

Tobias Grab

CTO

Youngsuk Kim

CFO